What is Supplier Relationship Management (SRM)?

Trying to build a business without suppliers is like building a house with no structural integrity; eventually, the entire thing will come crashing down. Maintaining a great relationship with your suppliers can help reduce business costs, optimise the value chain, improve the quality of your products and make technological advancements that place you ahead of the competition. Supplier relationship management is a way for suppliers and retailers to grow and develop alongside each other in order to get the most out of the supply chain, but how do you do it effectively?

What is supplier relationship management (SRM)?

Supplier relationship management (SRM) involves the ongoing organisation of different suppliers to create strategies for improving their performance within a supply chain. The purpose is to find ways to cultivate better working relationships to ensure optimal productivity to maximise value and minimise risk.

There isn't a universal agreement that lists the set of tasks covered by SRM, but, generally, it includes everything from choosing what suppliers you want to work with to the ongoing maintenance of those relationships. It also includes negotiating contracts, monitoring performance and predicting and resolving any issues that may arise. A successful SRM strategy seeks to save costs, reduce risks, maximise value, gain competitive advantage, and create ongoing improvements.

Origins of the term

The term SRM came into existence when Peter Kraljic, a director at the consulting firm, McKinsey & Company, coined the term in 1983. He wrote an article, 'Purchasing Must Become Supply Management' in the Harvard Business Review, where he discussed segmenting suppliers into profitability and risk groups. His main idea was that each supplier is different and therefore needs to be managed differently. His original framework has been built on and developed to create the version of supplier relationship management we currently use.

Examples of supplier relationships

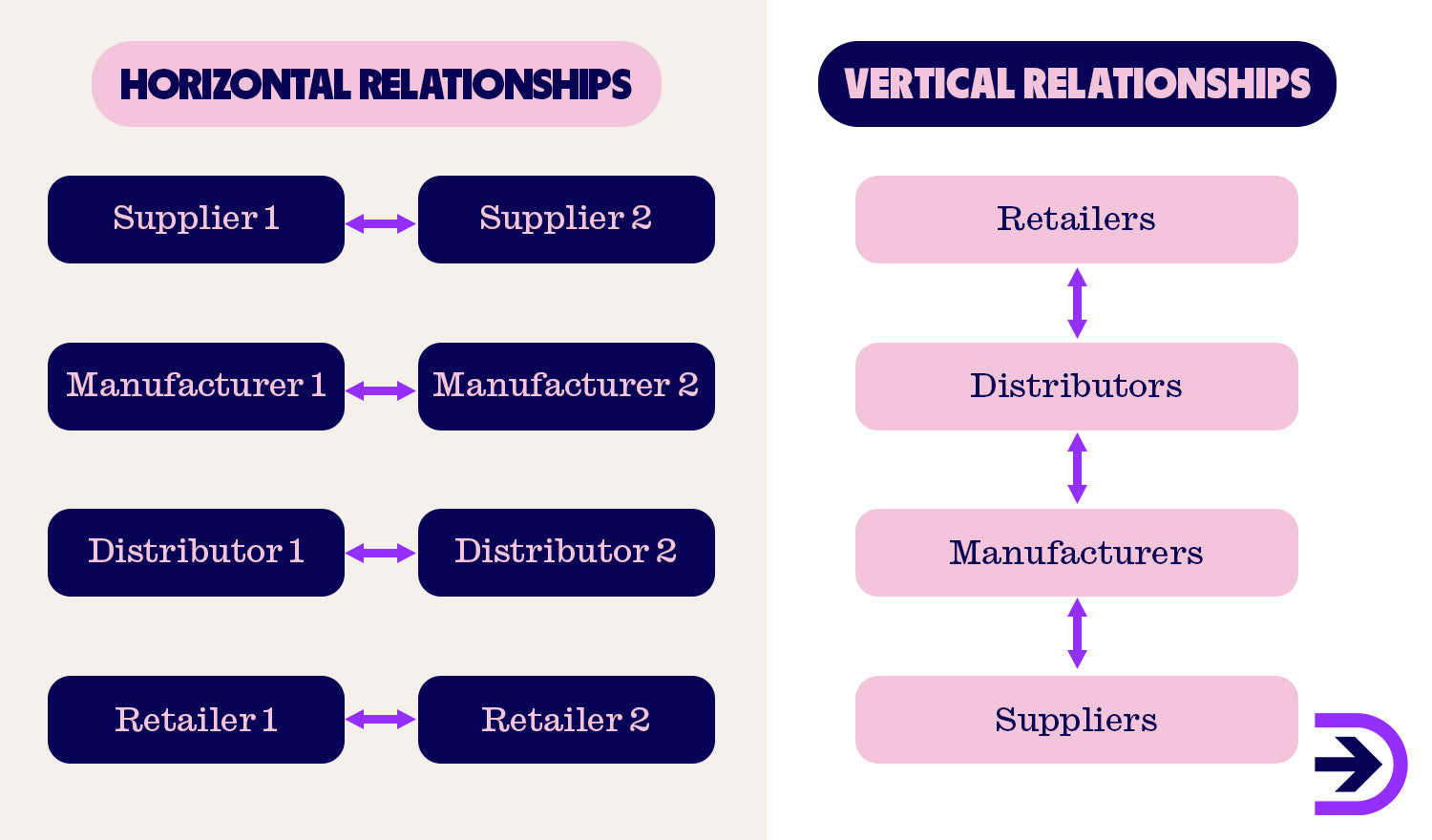

Supplier relationships are interactions between different businesses involved in the retail supply chain. There are two types of supplier relationships: vertical and horizontal supplier relationships.

Vertical supplier relationships are the more traditional model that simply involves transactions between retailers and their suppliers. On the other hand, horizontal supplier relationships work in conjunction. For example, you’re a TV manufacturer, and the suppliers of cables and speaker systems both deliver their parts to you, which means suppliers provide the same manufacturer with different materials to produce the end product. These two suppliers work collaboratively to achieve mutually-agreed business goals and require trust and collaboration to succeed.

A manufacturing company specialising in air purifiers would require an ongoing stream of raw materials to produce their products and sell them to wholesalers or retailers. They’ll need suppliers to provide them with production materials, which include plastic, electric fans, control panels and filters. In order to ensure timely deliveries and high-quality materials, a strategic alliance is beneficial so that each party is working towards a unified goal. The manufacturing company will also have a partnership-type supplier relationship with either distributors, retailers or wholesalers depending on the nature of their supply chain. This is a great way to produce positive results, and having trust in a relationship between suppliers will reduce supply chain risks and guarantee products are getting to customers quickly.

Core elements of the supplier relationship management process

Building strong supplier relationships take time, effort, and commitment, and investing in your professional relationships will directly correlate with your intended business outcomes and open up new business opportunities. Being honest and transparent with one another is one of the essential elements of building strong supplier relationships. You should engage in regular, open communication so that both parties can rest assured that neither business is looking to gain something at the expense of the other. Opportunistic approaches only seek to break trust, and with trust being the foundation of relationships, your relationship with your suppliers cannot work long-term without it, so you should always remain reliable and loyal. Successful supplier relationships are all about collaboration, communication and transparency.

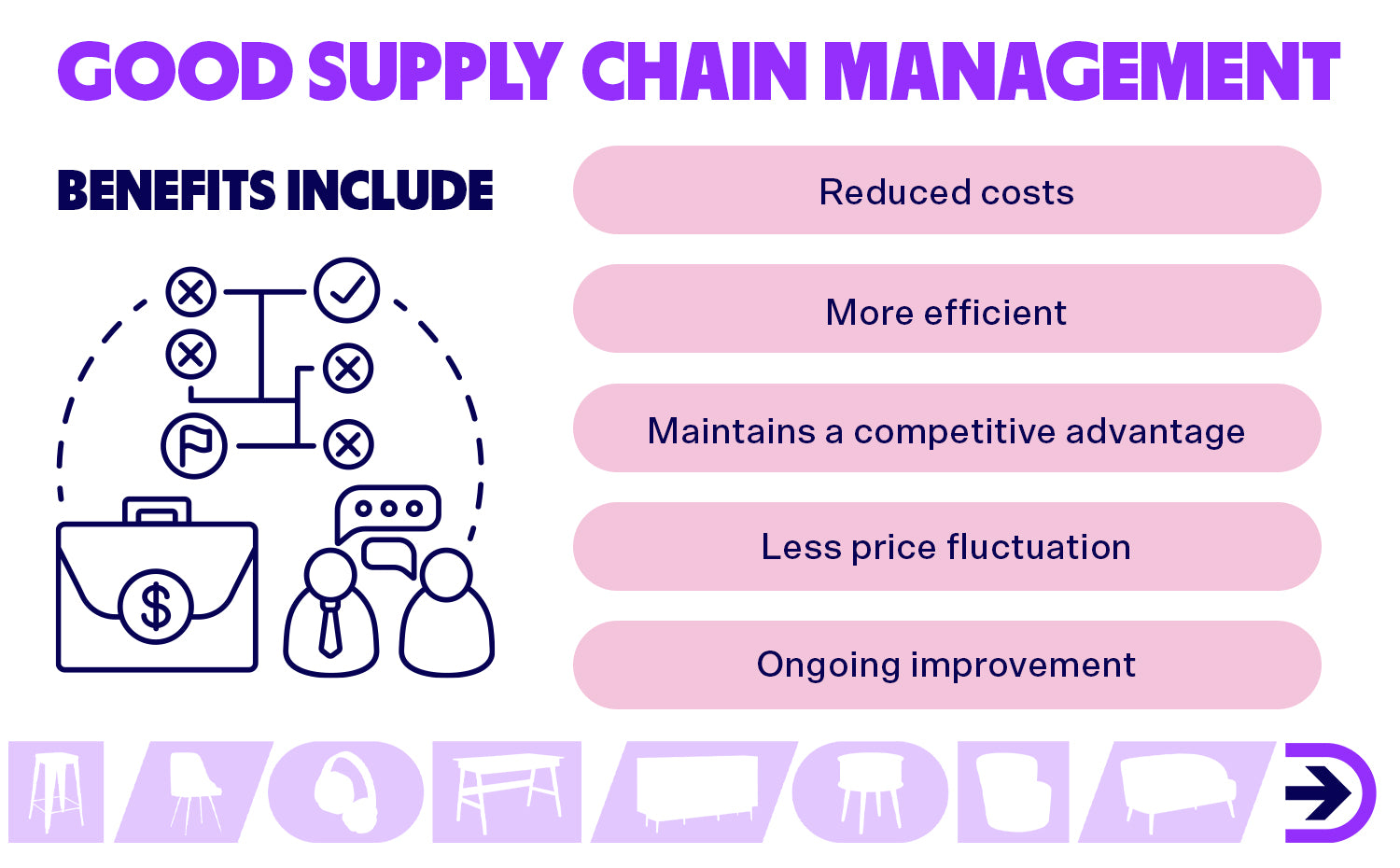

The benefits of good supply chain management

Reduced costs

Good supply chain management means you can save more in the long term. Modern consumerism calls for a constant stream of high-quality products, which means you may need to work with a wide range of suppliers. Having more suppliers means higher costs, but fostering great relationships with suppliers will mean that there can be more price negotiations to benefit all parties. You may find that over time you save money by being loyal to a particular supplier or by setting up things like bulk order discounts, long-term contracts with fixed prices and exclusive deals.

More efficient

Effective and ongoing management is the perfect recipe for increased efficiency and supply chain continuity. If your suppliers know your expectations and have the tools to meet those set expectations, they will start producing more efficiently. Furthermore, the delays in the supply chain will decrease because of proper risk management at every stage. SRM incidentally makes for effective customer relationship management and helps streamline the process of B2C.

Helps maintain a competitive advantage

A great way to get a leg up over your competitors is by offering the best products and services, and you can do it with effective supply chain management. Proper supply chain management is essential for improving the efficiency of your business. Your customers may also feel rewarded due to faster delivery times and an ongoing stream of products. There will be no more sold-out stock as your supply chain will adapt to changes in seasonality, and you and your suppliers will manage to accurately predict when products may become more popular throughout the year.

Less price fluctuation

There is no better way to upset customers than having prices that frequently change. The constant change in product pricing may shift customers' attention from the product's features to its price. Additionally, your repeat customers will quickly notice if the same products they have bought previously have increased in price. Such circumstances may become favourable for your competitors as your customers might look for products having reasonable and steady pricing. With ongoing supplier relationship management, you are more likely to negotiate fixed prices with your suppliers so that you don’t have to increase the retail price of your products and have adequate profit margins. Negotiations pave the way for long-term contracts developed by both businesses, which may include minimum order quantities and fixed prices so there are fewer price fluctuations.

Ongoing improvement

With your suppliers working closely and collaboratively, there's always a scope for ongoing improvement. Open communication and feedback will pave the way to improving the efficiency of your business. You’ll understand the needs of your suppliers, and they will begin to understand yours. You’ll know exactly when you need to order from your suppliers, and they’ll know when to expect the orders. This seamless working relationship will only garner constant improvement, and you can start implementing technological advancements to improve supply chain processes. Supply chain management is needed to evaluate risks because one of the worst things businesses can do is wait for delays in the supply chain and then act. For example, during the COVID-19 pandemic 75 per cent of businesses across the world were not prepared to tackle drastic supply chain changes, and subsequently faced problems that took them years to recover. Proper analysis is needed to effectively plan for disruptions so businesses can think of solutions to prevent disruptions in production. Ongoing supply chain management can help improve business operations.

Top challenges of supplier relationship management

Maintaining quality

The quality of your products will always be the responsibility of the supply chain, and without employing suppliers who are committed to maintaining quality assurance, there’s a risk of losing a big chunk of your customer base. One of the first steps to SRM is improving the efficiency of your supply chain. But there’s a fine line between ensuring your suppliers are producing at a desirable speed without running the risk of product faults and defects. You can improve efficiency without losing out on quality and putting your suppliers at risk, for which you need to have a proper plan in place.

Managing risks

There are many things that can go wrong in the retail supply chain; for instance, seasonality trends throughout the year, especially during Christmas, can cause products to sell out if you aren’t prepared. Global shortages and pandemics can disrupt suppliers, which might result in higher prices and a lack of materials. Any supply chain inefficiencies can upset customers and create unpleasant experiences related to your business. If you aren’t aware of the risks, you can’t mitigate them, so you should meet your suppliers and discuss the potential risks and solutions to combat them.

Meeting legal and compliance requirements

Depending on the products you are selling, as a retailer, there are plenty of legal and compliance requirements you must adhere to. If you’re selling something like pharmaceutical products or food and drinks, you need to ensure that your products meet the quality requirements for the safety of your customers. Sometimes, you may find it difficult to track how your suppliers produce these products or materials and if they’re compliant.

Managing costs

A big part of creating profit margins for your business is finding ways to cut business-related costs without jeopardising quality. Some retailers can be too focused on finding the cheapest suppliers, which may result in poor-quality products and poorly managed supply chains.

Steps to effective supplier relationship management

Assessing supplier capabilities

When you’re working with multiple suppliers, determining the ones classified as showing strategic potential is crucial. Ask yourself which suppliers you will work with vertically and horizontally, who you will have open collaborations with and who will work transactionally.

There are many ways to evaluate your suppliers, such as scorecards that give you a snapshot of how well a supplier meets your criteria, i.e. price, quality, flexibility, risk, and convenience. Supplier questionnaires can also provide measurable data to review and compare capabilities easily. You can set up meetings with suppliers to better understand their production methods and start to discuss payment strategies. Having open and honest communication is essential to set the standard for your ongoing supplier strategy.

You’ll want to work with suppliers who will support your business goals, like suppliers who specialise in the kinds of products you sell. You’ll also want them to be reliable, so look for evidence that they can provide on-time deliveries with minimal disruptions. Choose suppliers that offer low costs and deliver high-quality products with proper distribution practices; you don’t want your product orders constantly arriving damaged or faulty.

You’ll also choose the types of businesses you are going to work with, and that might be anything from wholesalers to distributors, all the way to suppliers and manufacturers. Wholesalers will purchase and sell products and goods in bulk at discounted prices, and distributors oversee the safe transporting of those products between suppliers and wholesalers. Manufacturers are in charge of making the product magic happen by assembling your products. Sometimes, you may find suppliers doing each of these jobs on behalf of retailers, but chances are you'll have to rely on multiple suppliers.

Create a strategy

As the supplier relationship manager, at this point, you should start thinking about the KPIs you want to achieve. A company like Toyota, which is well known for being among the best in the business at managing supplier relationships, says that of their 250 suppliers in their European sector, all have relevant KPIs to evaluate their suppliers. Having measurable goals is crucial as it can give you reliable data to build the foundations you need to create your supplier strategy.

Split up your suppliers based on specialisation as each supplier will require a different strategy. As we have discussed, you should nurture your relationship with your suppliers so that both parties have a good chance of success. Think about the kinds of technological systems you might need to remove or anything that could jeopardise the relationship, like automated payment systems or re-order points that alert you when you’re running low on a particular item. Setting up supplier risk management is crucial, so discuss with your suppliers any potential risks or blockers and how to manage them effectively, which can help them to perform well.

Contracts and negotiation

Each supplier you work with will require a different contract. This negotiation stage is a chance for both parties to make clear their terms and conditions, such as minimum order quantities or payment terms. If you’re working with wholesalers, they may have a retail price you must meet to sell their products to ensure you make a profit without making the products overpriced. There may also be other things, such as return and exchange policies for faulty, damaged or unsatisfactory products, which you may want to discuss. The sole purpose of these negotiations and contracts is to protect all the businesses involved in the supply chain.

You can also negotiate payment times and the consequences of late payments. In order to foster great relationships with your suppliers, you should always pay them on time. If, for some reason, your payment may be a few days late, you should also include a clause in your contracts to allow for this.

Relationship building

Focus on creating a mutually beneficial relationship with businesses involved in the supply chain. The idea is that you are forming lasting relationships so that every supplier you work with feels comfortable having an open and honest conversation with you. The better your supplier understands your business strategies and goals, the more likely they will be able to meet them. Furthermore, fostering trust between retailers and suppliers is more likely to create loyal business relationships, ensuring that no party feels compelled to turn to competitors.

Performance management

Once you have established terms and conditions and started building relationships with your suppliers, ongoing supplier performance management is needed. It’s no good putting your time and effort into something that fails to meet your expectations. Supplier relationship management is an ongoing process that will help to mitigate costs and reduce future risks. It is a great idea to set up regular meetings with your suppliers to address any problems or concerns and discuss how operations can improve so your business can get the most out of your supply chain.

Using SRM tools and software

Using technology allows you to accurately trace every step of the supply chain and identify shortcomings. It will also help you develop specific plans for each of your suppliers.

To facilitate B2B interactions, there are many SRM tools and software to view supplier data. The AI’s ability to rapidly generate data-driven insights can help retailers assess supplier performance data and give instant snapshots that may have otherwise taken hours.

Some platforms can directly support supply management. Once tedious jobs, such as purchase order management, supplier onboarding and performance management, can now be easily handled. In 2023, some of the best SRM software includes platforms like:

Using Dropshipzone to find suppliers

If you want an easier way to find reliable and strategic suppliers, you can rely on Dropshipzone. Suppliers are all in one place, and you can easily change suppliers until you find the right one to work with. It also allows you to integrate products seamlessly into your online store. With its ease of use and 24/7 assistance from a dedicated team, you can dedicate your time to building strategic supplier relationships and ongoing performance management. The best part is you don’t need to hold any physical inventory; our trusted Suppliers take care of all the shipping and handling on your behalf. Sign up today with Dropshipzone to sell more, more often.

.png)